Reducer Tomasetto AT-09 Alaska Autogas Reducer for up to 130BHP sequential engines

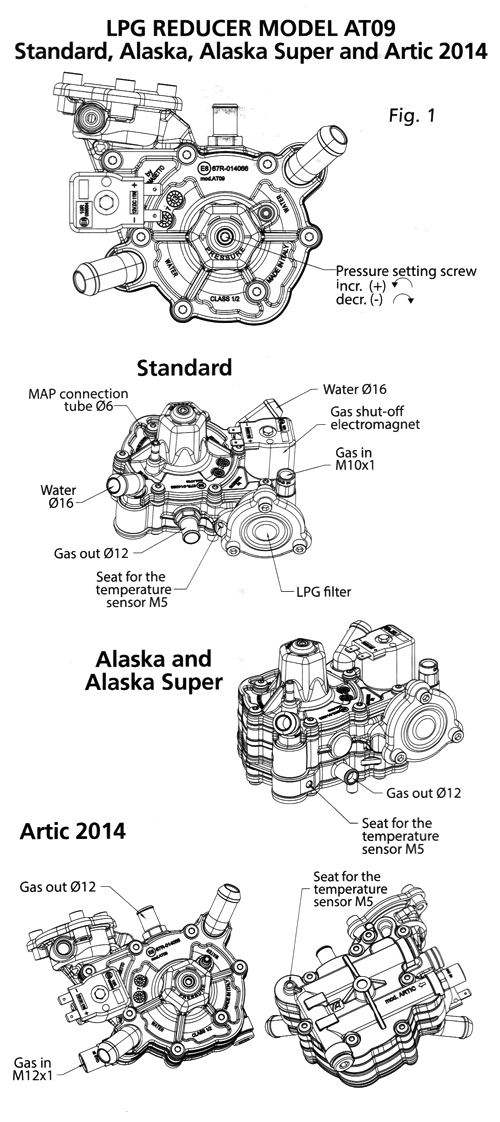

The model AT09 Alaska version LPG reducer is a single stage reducer for LPG sequential injection systems, homologated ECE 67R-01.

Equipped with filter unit and inlet solenoid valve, compared to basic version it has also an additional post-heating of the LPG at the outlet, that allows higher gas flow and higher gas temperature at the exit. Alaska version is suitable for engines with power from 90 HP to 140 HP and with temperature not lower than -10 °C. With lower temperatures the reducer could not be sufficient to follow the maximum power requirement from the engine.

The pressure at the outlet is adjustable from 0,9 to 1,8 bar (pressures referred to reducer not connected to the engine).

Technical specification:

- Material Aluminium die cast body

- Weight 1.5 kg

- Dimensions 120x125x105 mm

- Max. inlet pressure 3 MPa

- Outlet pressure variable from 90 to 180 kPa (when not connected to engine)

- Solenoid voltage 12 V DC

- Solenoid absorption 17 W

- Inlet connection M10x1 pipe Ø6 mm

- Outlet connection Fixed fitting Ø12 mm

- Engine power from 80 to 135 HP, with T>-10 °C

INSTALLATION Manual for Alaska Artic Autohgas Reducer Vapourizer

• The reducer has to be placed inside the engine compartment, possibly in a position that easily allows its setting and maintenance. The outlet gas connection has to be positioned upwards.

• The reducer has to be possibly installed under the level of the drip tray of the engine cooling circuit, avoiding to fix it to the engine or other heating/vibrating elements that may shock or damage it. The minimum installation distance from the engine exhaust manifold or other heating elements shall be, at least, 150mm. If the distance is lower, the use of a steel diaphragm (1mm thickness) or equivalent material is recommended.

• To avoid impure Les entering the regulator, verify the pipes cleanness before the connection, while, to avoid any possible pipes bending, verify that there is no abnormal tension in the connections,

• Connect the copper pipes to the reducer gas inlet/outlet using the fittings and joints supplied by Tomasetto. The fittings shall be fixed with a max. tightening torque of 5mm. An excessive torque may damage the tubes, affect the regular flow rate and, possibly, lead to leakages.

• Connect the reducer water circuit to the engine cooling system. The connection shall be made parallel to the passenger compartment radiator, by means of two T-fittings.

• Connect the coil in accordance with the electronic diagram of the ECU and verify that the wires are electrically insulated.

• After the installation, verify any possible gas leakages presence using gas detectors.

Warning: Do not approach the vehicle with flaming objects, such as cigarettes, or elements that may cause sparks. Do not remove the reducers cover screws to connect the NTC sensor.

ADJUSTMENT

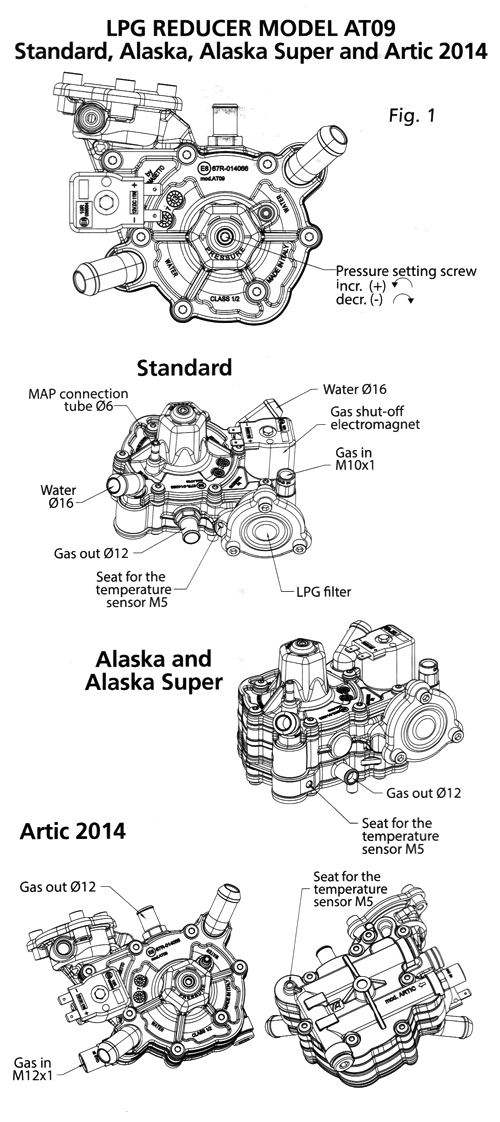

After the reducer installation, it is necessary to modify the injection pressure, according to the system requirement, by turning the adjusting screw on the reducer cover (fig.1). Considering that the pressure influences the injection timing, the adjustment procedure shall be made in accordance with the supplier's Electronic Control Unit guidebook. The injection pressure setting is recommended before proceeding with the ECU setting at the idle, in order to ensure the LPG system stability and avoid deviations from the injection setting values.

MAINTENANCE

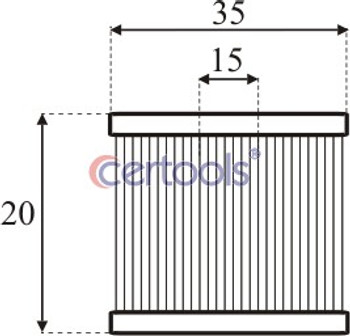

At least once in a year, or every 20.000 km, it is suggested to maintain the filter unit with the proper original Tomasetto kit. A complete maintenance is recommended every 50.000 km or 3 years or if the car remained unused for a long time (1 year) , by using only the original Tomasetto maintenance kit. A complete revision should be, anyway, more frequently performed in case of dirticontaminants presence in the water or gas circuit.

WARRANTY

the Manufacturer guarantees that each device has been manufactured according to the applicable Regulations and 100% calibrated and tested. Without any different written agreement between the Parties, Tomasetto guarantees that the Products are free from manufacturing defects for a period of 24 months from their production date. If the Customer claim is covered by warranty and notified within the terms indicated in this paragraph Tomasetto, at his discretion, will replace or repair each Product or its parts. The defective Product shall be sent to Tomasetto free of charge, with its accessories, not tampered, accompanied by a document indicating the defect.

In any case, warranty will not cover defects caused by damages during transport; not proper or wrong use; degradation by normal use; non-compliance with Tomasetto instructions related to functioning and maintenance of the Products; improper storage; repairs or modifications made by the Customer or by others without previous written authorization by Tomasetto; usage for applications different than automotive.

Tomasetto LPG pressure reducer, model AT09, is a 2 stages electronic reducer suitable for sequential systems. The use and the installation procedure of this pressure reducer are limited to what specified in the European Regulation ECE 67R-01. Any different use causes the immediate warranty decay and the Manufacturer exclusion from any responsibilities.