Description

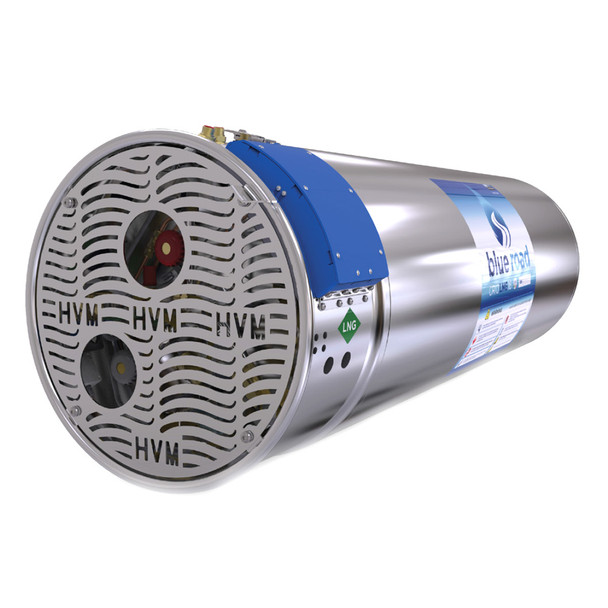

LNG Cryogenic Tank 200 - 450 Litres capacity

Liquid Natural Gas is a methane gas under very low temperature around -165deg. Celsius which needs to be stored in cryogenic tanks as the offered one.

Available sizes:

| Net capacity [L] | Length (mm) | Weight empty (kg) | Weight filled (kg) | Max working pressure (bar) | Hold time (days) |

| 175 | 1165 | 163 | 236 | 16 | >5 |

| 234 | 1390 | 185 | 281 | ||

| 316 | 1715 | 218 | 348 | ||

| 345 | 1830 | 230 | 372 | ||

| 408 | 2090 | 255 | 423 |

Technical specification:

- First European tank on the market equipped with a cryogenic solenoid valve according to ECE ONU R110.

- Horizontal fuel tank for use with liquid natural gas (LNG) with a capacity ranging from 200 to 450 litres (see configuration table on the next page).

- Preset tank for left or right filling connections which allows warehouse stocks management and a fast mechanical assembly.

- Maximum performance in terms of reliability, strength and durability of the tank.

- Electronic level indicator with 8 bright leds.

- Super insulation system with high vacuum which providesa low rate of evaporation.

- Automatic fuel excess flow valve according to R110 regulation.

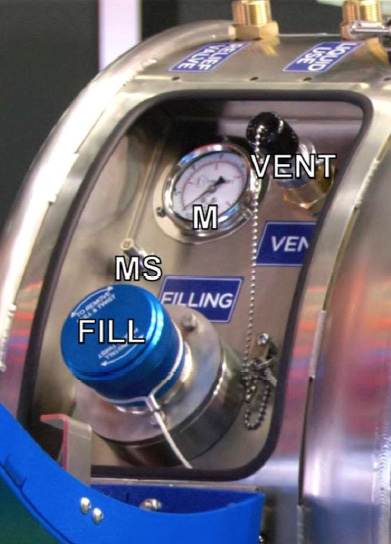

- Protective cover with security key which protects the filling connections and control unit.

- A proximity sensor which stops the engine to ensure safe and rapid filling.

- Equipped with 4 relief valves.

- A signal output level indicator 0-5 V allows communication with the engine control unit for the calculation of an average fuel economy.

Accessories:

- Support bracket for tank installation on vehicles according to R110 regulation.

- Heat exchanger / external evaporator.

- External piping connections for system assembly on vehicles.

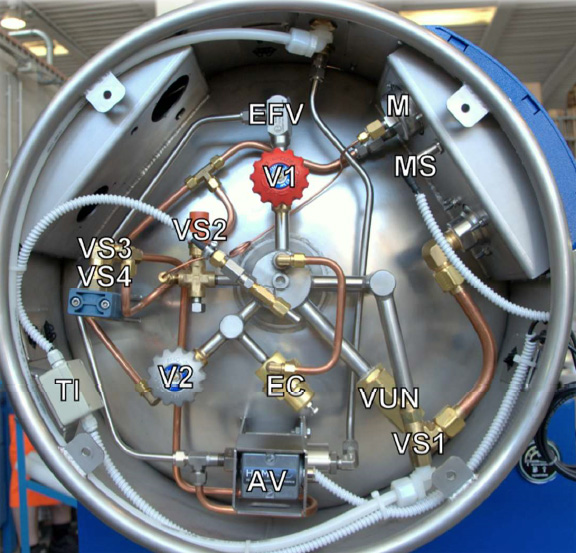

VS1 - Primary Relief Valve 16bar

VS2 - Secondary Relief Valve 18bar

VS3 - Filling piping Security Relief Valve

VS4 - Venting piping Security Relief Valve

V2 - Vent Valve

PV - Evacuation Port

EC - Economizer

V1 - Liquid Valve

EFV - Excess Flow Valve

AV - Automatic cut off valve

VUN - Check Valve

FILL - Filling Receptacle

VENT - Vent Receptacle

M - Pressure Gauge

I - Level gauge

TI - Level transmitter

PT - Pressure transmitter

MS - Magnetic sensor

![CHART LNG Tank 352 Litres 16bar [USED] CHART LNG Tank 352 Litres 16bar [USED]](https://cdn11.bigcommerce.com/s-0baae/images/stencil/350x350/products/3056/13005/600008-1__75736.1717507890.jpg?c=2)

![CHART LNG Tank 352 Litres 16bar [USED] CHART LNG Tank 352 Litres 16bar [USED]](https://cdn11.bigcommerce.com/s-0baae/images/stencil/350x350/products/3056/13002/600008-5__30678.1717507886.jpg?c=2)